Now, let’s talk about these “evaporator tubes.” Folks might wonder, what’s an evaporator tube even for? Well, let me break it down in simple terms. Evaporator tubes are these important little things you find in big machines that cool or heat stuff up. They’re real common in places like fridges, air conditioners, and even those huge systems in power plants. You see, when you need something to change from a liquid to a gas, evaporator tubes come in real handy. But let me tell ya, there’s more to these tubes than just making things colder or warmer.

How Evaporator Tubes Work

Now, I know it sounds fancy, but the way these tubes work ain’t too hard to understand. Inside the tube, there’s usually some kind of liquid – could be a refrigerant like in a fridge, or some other liquid in bigger machines. This liquid flows through the tube, and as it moves, it picks up heat or loses it. That’s where all the magic happens. When the liquid heats up enough, it turns into gas. Then that gas can move along and do its job, cooling or heating other parts of the system.

Why Evaporator Tubes Need to Last Long

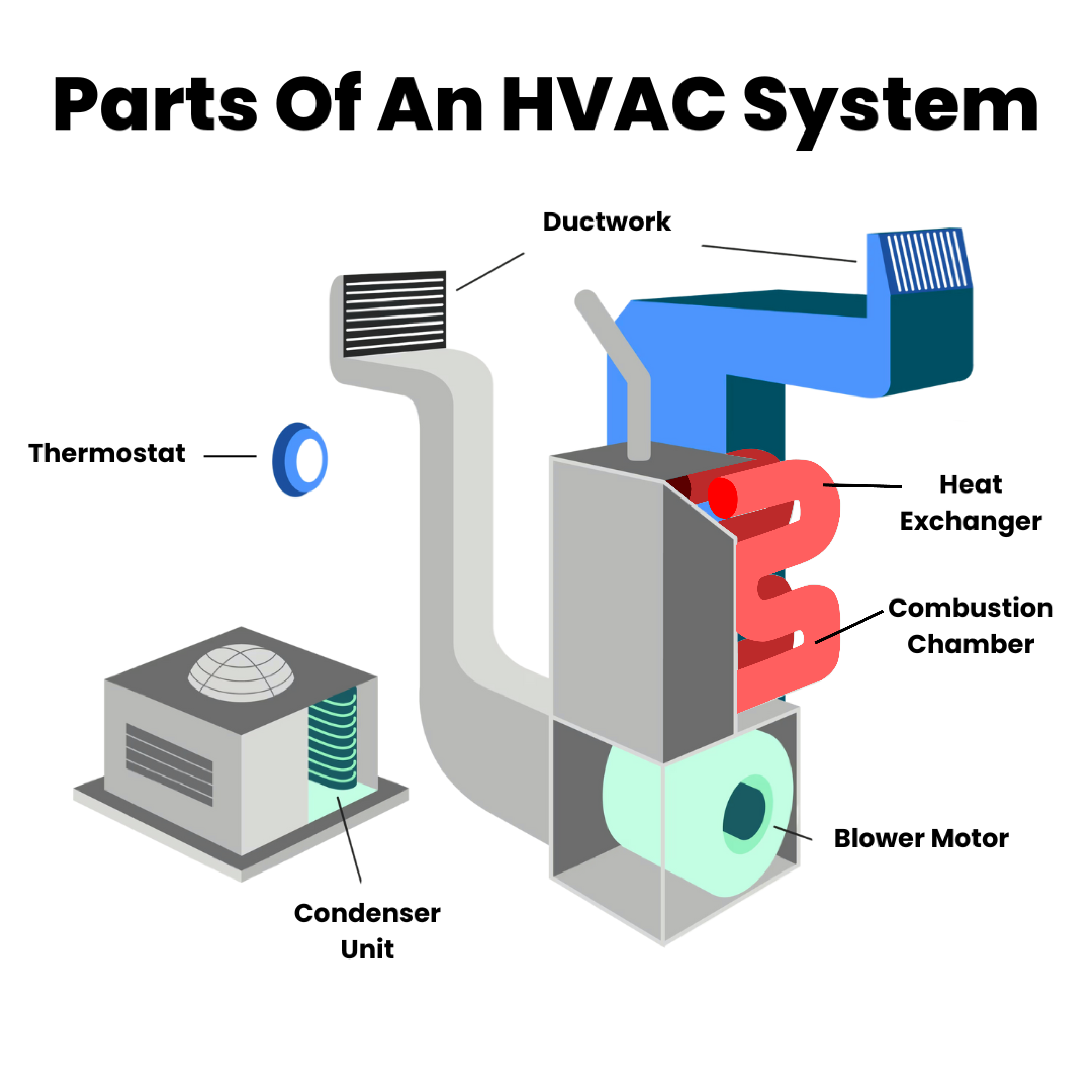

Now, here’s the thing with these tubes – they gotta be strong and last long. See, if they start breaking down, the whole system can stop working. That’s a big deal, especially in things like HVAC systems, where folks rely on them to keep cool air coming. The problem here is something called corrosion. When metal tubes get exposed to water, chemicals, or just plain old air, they can start rusting or corroding. If you’ve ever seen an old metal pipe all rusty, that’s what I’m talkin’ about.

Corrosion Prevention Tips for Evaporator Tubes

Now, corrosion is a real troublemaker for evaporator tubes. But there are ways to slow it down. One of the best things folks can do is pick the right kind of metal for these tubes. For example, stainless steel is a good choice ‘cause it doesn’t rust as fast. Sometimes, people also add a special coating on the tubes, which makes it harder for rust to get in. The coating kinda acts like a shield, protecting the metal underneath. It costs a bit more upfront, but it can save a whole lot in repairs down the road.

Different Types of Evaporators Using Tubes

Now, not all evaporators are the same. Some have a single tube running through them, while others, like plate surface evaporators, got two plates stuck together with a tube in between. These plates are often made of aluminum ‘cause it’s real good at moving heat around. In this type, the refrigerant flows in that little tube between the plates, which helps cool or heat whatever needs cooling or heating.

Then there’s something called a shell and tube flooded evaporator. In this type, the liquid sits outside the tubes instead of inside. It’s in this big shell around the tubes. When the liquid heats up and boils, it creates bubbles on the surface of the tubes. This bubbling can happen two ways – either by nucleation (little bubbles popping up here and there) or by film (where the bubbles form a layer). This kind of evaporator is used in bigger systems, like power plants, where they need a lot of cooling power.

How to Keep Evaporator Tubes in Good Shape

Now, just like taking care of anything else, there’s some work to be done to keep these tubes in good shape. Here’s a list of things that might help:

- Regular Cleaning: Dust and dirt can pile up on the outside, which messes with the cooling or heating. Give them a wipe down every so often.

- Inspection for Cracks or Rust: Every once in a while, give those tubes a good look. If you see any rust or cracks, it’s better to fix it early than let it get worse.

- Using Quality Materials: Like I said before, using materials like stainless steel or aluminum can help make tubes last longer.

- Coating for Extra Protection: Adding a special coating can make a big difference, especially if the tubes are in a rough environment.

Why Evaporator Tubes Are Important for Big Systems

Now, for anyone who’s not sure why we’re even talkin’ about evaporator tubes – here’s the scoop. In big places like supermarkets, hospitals, and power plants, keeping things at the right temperature is real important. Without these tubes, the whole system wouldn’t work right, and that could lead to all kinds of trouble. Think about a hospital needing to keep medicine cool, or a grocery store keeping all that food fresh. Evaporator tubes help make sure that cooling happens.

In Conclusion

So, there you go – a little look into what evaporator tubes do and why they matter. They might seem like just small parts, but without ‘em, a lot of big systems would be in a heap of trouble. From picking the right materials to keeping an eye out for corrosion, there are ways to make sure these tubes last longer. And that means less fixing and more reliable cooling or heating, no matter where you need it.

Tags:[evaporator tube, corrosion prevention, HVAC systems, plate surface evaporators, shell and tube flooded evaporator]